Article by: Paul Axford

Applies to: All models with the M30 big six engine (this article was written with a 730i). Note: some variations exist with early renditions installed in e9 and e12 models.

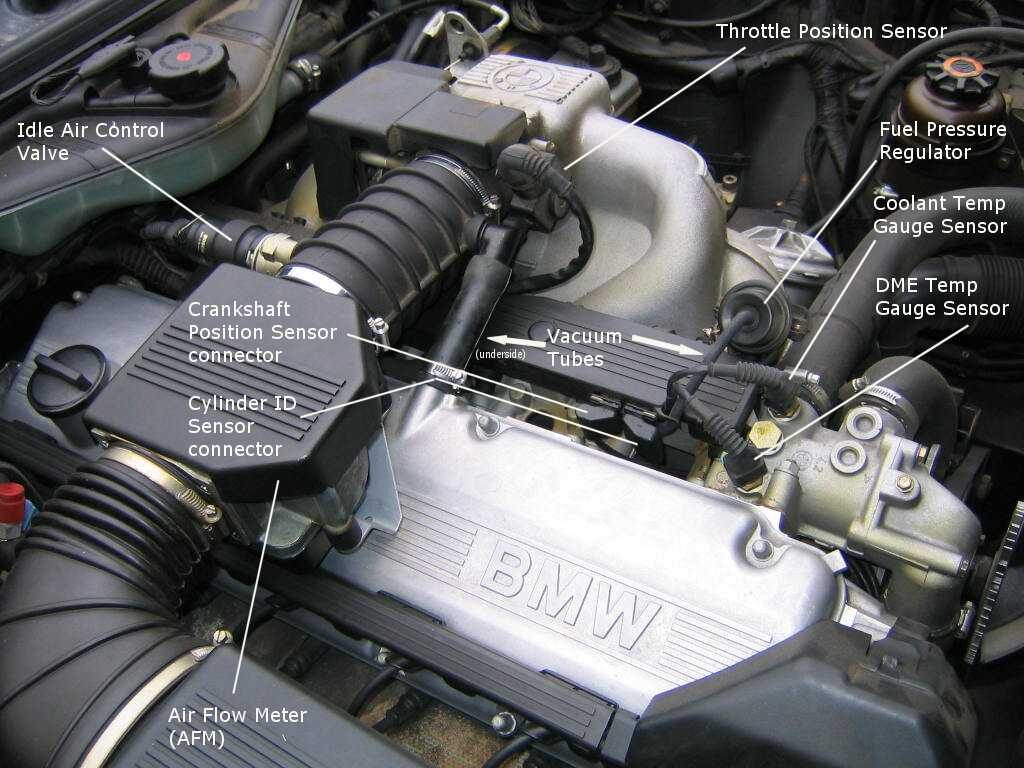

The photo below indicates where some of these sensors are located.

a) Cleaning the high-tension ignition components.

I removed the distributor cap and rotor for cleaning. The inside of the my cap was a bit dirty.

I washed the parts in soapy water as these can’t be easily and cheaply replaced in NZ.

It pays to note that the glossy finish on the red plastic resin is fragile and should not be cleaned with an abrasive.

I also wiped down the plug wires and caps with a mentholated spirits. One of the plug caps was slightly mangled so I filled the holes with silicone RTV.

I checked the resistance of some of the wire assemblies – no problems there and none expected.

b) Replacing the two small vacuum tubes.

Although the original tubes were not leaking, they were severely deteriorated.

The new rubber tubing should have an ID of 4mm and one meter length is sufficient for both applications.

One supplies vacuum to the fuel pressure regulator such that the pressure is maintained relative to intake manifold pressure.

The other draws air from the middle of the crankcase breather tube, although it looks simply like a designed-in bad vacuum leak to me.

I think this tube combined with the large breather tube mimics the PCV valve function seen on other cars.

c) Checking the Crank Position Sensor.

This is a “Hall Effect” type sensor mounted .030″ – .050″ from a toothed wheel on the front end of the crankshaft.

I checked the gap, the alignment with the wheel, and the resistance spec at the connector as 540 ohms +/-10%.

d) Checking the Cylinder Identification Sensor.

This little gem is located on the No. 6 cylinder HT wire as it exits the distributor cap and provides a signal to the DME when that cylinder is fired.

According to roadfly.com wisdom, the only purpose of this is to allow the DME to coordinate fuel injection pulses (into two sets of three injectors) with cylinder firing for a smoother idle.

Apparently it’s not that important that it works – a good thing as spares are reputed to be hard to come by. Currently I don’t what the correct value should be.

e) Checking the DME Temp Sensor.

The spec from Bentley is 270 – 400 ohms at 80° C (176° F), 2K1 – 2K9 ohms at 20° C (68° F). Mine was 260 and 2K7 ohms.

Editor’s note:

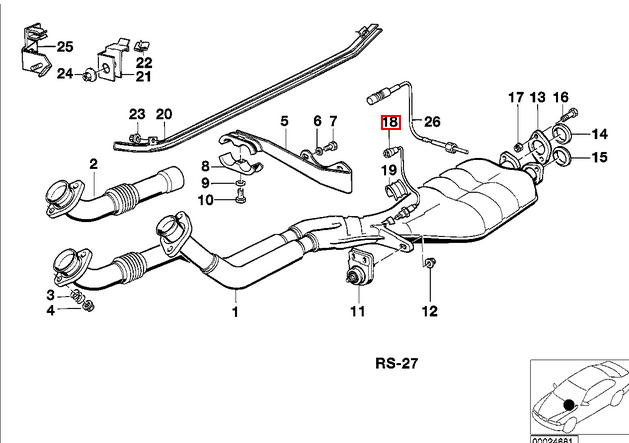

In addition to the sensors listed above, one of the most important sensors to consider is the oxygen (O2) sensor.

This sensor has a lifespan of about 100,000 miles before it needs to be replaced.

Once past it’s lifespan, the ECU will default to fuel mixture settings that are extremely rich (as a means of protecting the engine).

This equates to poor engine performance and very bad fuel consumption. This sensor (positioned in the graphic below) must be replaced at regular mileage intervals.