Article by: Johan

Article applies to: all e24, e28, e32, e34 models with the M30 inline 6 cylinder engine.

Problem: There are countless reasons why you might want to replace your engine.

You could be leaking fluids badly, you could be low on compression, you could have a head gasket failure where the engine overheated badly, or maybe you just think the mileage is too high.

It could also be that swapping the engine is cheaper then getting new parts from the dealer for a repair.

At the scrap yards the M30 cylinder heads are worth a bit of money and the short block is useless as they barely break.

Having enough water in your engine for goldfish to swim in will cause corrosion.

A hole in your piston also isn’t good. (picture from ebay auction.

Or maybe you just dropped your engine 🙂 (picture “stolen” from Rob Nicol).

What fits in a M30 powered e32?: The only direct fit into a 735i is an M30 3.0 or 3.5 out of an E32 or E34.

The earlier model M30s will not fit as the oil canister points downwards where the e32 has its engine mount bracket. Even if you swap the oil canister it won’t.

You will not get any oil pressure from the new style canister on the old block. Another difference between the engines is the oil pan, the oil pump and the oil-level sender.

You can replace it with another engine that was a factory fit for the E32 like the M60 v8 or the M70 v12. But be prepared to do lots and lots of work.

For example the I6, v8 and v12 all have different locations for the brake booster and the ABS pump.

When “upgrading” to a v8 or v12 you also need the gearbox and the final drive. So it’s cheaper to part out your car and buy a v8 or v12 powered E32.

The S38 (3.6 and 3.8) out of the E34 M5 should be a direct fit into the engine bay as it’s based on the M30.

But you still have some minor problems to work out as the air intake system is on the left side of the engine.

There are some people on the net who have installed this engine successfully. They usually take along the manual gearbox for performance reasons.

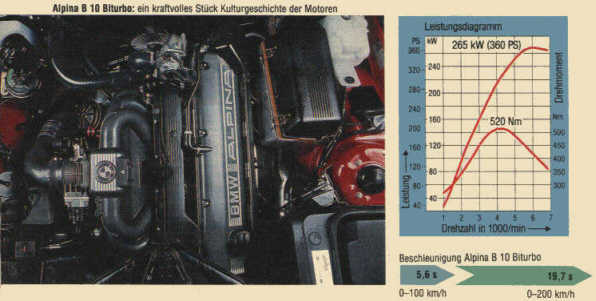

All M30 based Alpina/Hartge/Schnitzer engines will fit. But just try to get your hands on one for a reasonable amount of money.

And then it still has to be complete. Alpina for example won’t sell any parts unless you can prove you own a car that uses them.

But if you do have the cash (and we all know you don’t) go and trash an E34 Alpina B10 Bi-turbo for this little beast with 360 bhp/520Nm torque.

Downside is there are only 507 originally build.

The M30 engine:

The M30, also called big six, has been around quite a bit longer then I have.

It was used in a wide variety of body shapes among which: E12, E28, E23, E9, E3, E34, E32 and E24.

I’ve been in contact with someone who had a maritime version of the M30 which was apparently made especially for use in boats.

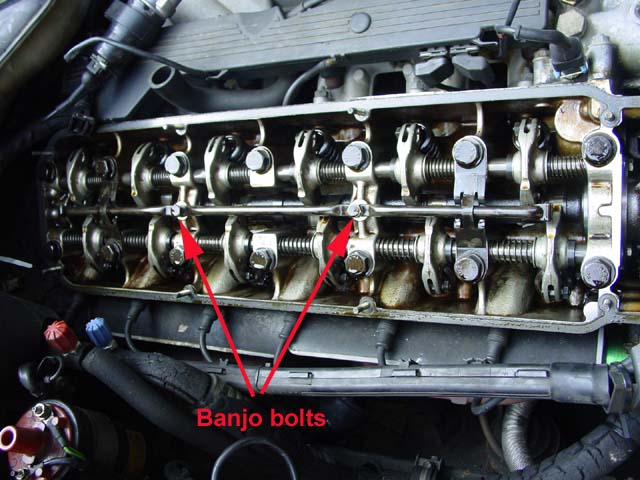

The M30 has a reputation for eating camshafts and head gaskets. This is not a real weak point of the engine.

It’s more a weak point of the owner. The camshaft is lubricated by an oil spray bar. The bolts on the oil spray bar tend to work loose after some time.

So you might want to check up on them regularly.

As the M30 has a cast iron short block with an aluminum cylinder head it’s quite sensitive to temperature changes.

So the cooling system has to be in proper order. That means you have to change the coolant every two years. I got some tips on this from a BMW classic car specialist:

- flush the coolant system every two years

- take out the radiator and shake the debris out when flushing

- poke around the coolant drain hole on the engine to remove any debris that might have accumulated there.The M30 is also very sensitive during its warm-up and cool down phase. So be sure the engine is up to operating temperature before you floor the accelerator. Keep in mind that the proper operating temperature isn’t reached when the temperature gauge is at the 12 o’clock position. That’s only the coolant temperature not the oil temperature. When you have driven your car at high speeds let the engine idle a bit before shutting it off. You can use this time to collect the junk in your car and put your sunglasses away.If you maintain the engine properly it will last at least 500 000km without anything serious going wrong. The classic car specialist has quite some customers to prove this. To bad he has even more to prove the head will crack if you don’t. But hey it keeps him in business 🙂

Inspecting the donor engine: Before buying a donor engine you might want to check the overall condition of the engine.

- If it has been pressure washed ask yourself why. Does the shop wash all the engines or just the ones that leak?

- Lift the valve cover and check the camshaft for wear. To do this run your nail over all the cam lobes. if it’s smooth your nail slides right over the whole lobe, if it’s worn your nail will detect the surface difference.

- Check the oil colour and signs of coolant.

- Check the spark plugs. My donor engine was supplied with 3 Beru plugs and 3 Bosch plugs. Not a sign of proper maintenance.

- They where also covered with a lot of carbon buildup. Not that strange when seeing the distributor and the plug wires.

Preparing the new engine: When the engine is out of the car it might be a perfect moment to replace some parts you won’t be able to reach after fitting the engine to the car.

Things that come to mind are the rear crankshaft seal, the transmission seal and the oil pan gasket.

Not the cheapest things but just imagine how much you are going to cry when the donor engine leaks after your test run.

I decided to reuse all the injection system parts of my old engine as I knew those where in working order.

I also transferred my starter motor (it still had a recent parts sticker on in), water pump and intake and exhaust manifolds.

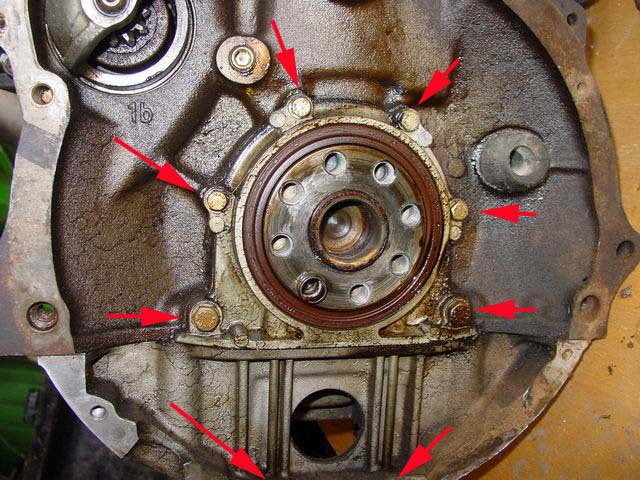

Replacing crankshaft seal

First remove Mr. flywheel. BMW uses a special tool to block the flywheel.

As I didn’t have this tool I used an impact wrench to undo the 8 bolts holding the flywheel to the engine.

Remove the bolts holding the seal housing. That includes the two from the oil pan.

I used a screwdriver and a hammer to drive the seal out. And I must say it was mounted properly!

After removing the old seal carefully hammer the new seal into the seal housing.

The new seal came with a plastic piece in the middle. That is actually the “tool” to refit the seal (when it’s already in the housing) onto the crankshaft.

It may be an expensive seal but hey it includes a tool! (Which probably cost under 2 cents)

Before replacing the seal housing back on the engine clean the gasket area’s on engine and seal housing with a gasket scraper and install a new gasket between the seal housing and the engine.

Now here is how to use the plastic “tool” to fit the seal and it’s housing back onto the crankshaft:

If you are not replacing the oil pan seal at the same time you may want to use some liquid sealant to keep the oil pan gasket from leaking.

The BMW manual says you can’t reuse the flywheel bolts and you must use locktite to hold the bolts in place.

Oil pan gasket

You have to remove all one million 10mm bolts before you can take the pan of the engine.

You might need to tap it gently with a plastic or rubber hammer to persuade it to come off.

Now clean off the old gasket. You will have to be careful as its aluminum and it scratches easily.

I was planning on scraping off the big parts with a gasket scraper and then using a spray can of chemical gasket remover.

But the aerosol didn’t have any gas anymore so i have to scrape it all off the with gasket scraper.

Reinstalling the gasket between the pan and the engine didn’t go that well as the gasket preferred to fall into the oil pan.

So I used some zip ties to keep the gasket in place until most bolts where in place. Then I cut the zip ties and fixed the oil pan properly.

Removing the big hunk of junk:

This isn’t meant to be a step by step instructional on how to remove the engine.

I just didn’t take enough pictures for that and if you need step by step instructions you might want to reconsider doing an engine swap.

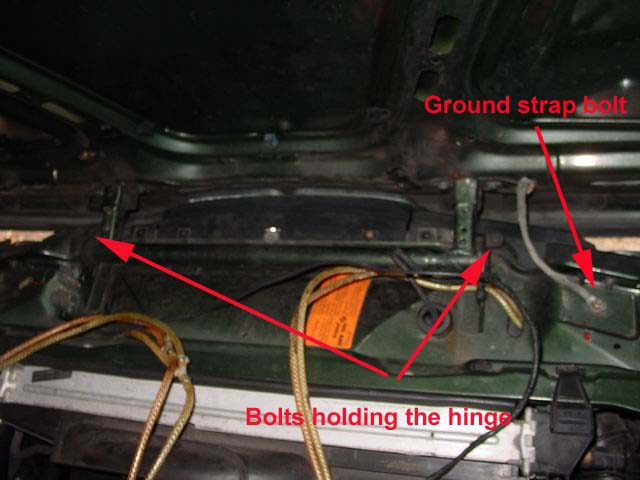

Removing the hood/bonnet gives a lot of extra space so let’s start with that.

The easy way to do this is to remove the bonnet with the hinge left attached to it. This way you don’t have to realign it after you are done.

First remove all the plastic clips holding the insulation to the hood/bonnet. Just pry the center parts out about 1cm and pull the clips out.

After that remove the wiring for the light, the light switch and the heater window washer jets.

Next remove the windshield washer fluid lines. Then remove the two bolts holding the hinge and the ground strap.

The clips holding the support on both sides:

Now that you have removed the hood/bonnet remove the plastic belt protection plate from under the car.

Now that you can reach everything from the front you can start to remove the bigger parts that are in the way.

Those parts would be the radiator+fan and the air filter box.

To remove the fan coupling give your 32mm box end wrench a good whack with a hammer.

Remember it’s left handed thread.

There are two ways to drain the cooling system: the slow and relatively clean way or the fast and messy way.

The clean way would be to undo the fragile radiator drain plug and the engine drain plug.

Of course I used the fast way which is undoing the lower hose of the radiator and leaving the rest in the engine.

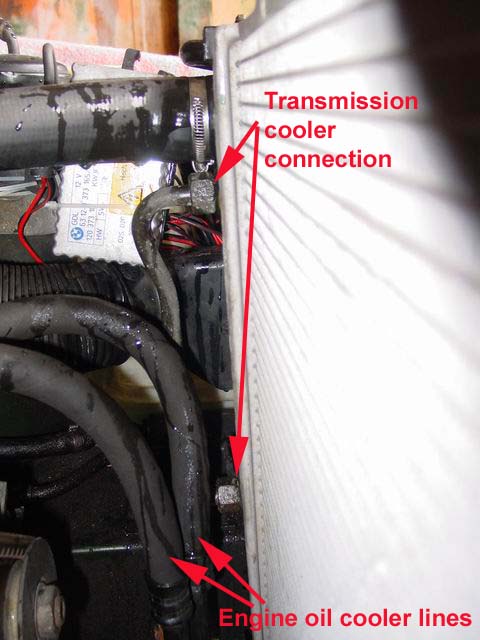

Undo the transmission cooler lines, the upper coolant hose and slide off the oil cooler from bottom of the radiator (if applicable).

Ah finally some workspace!

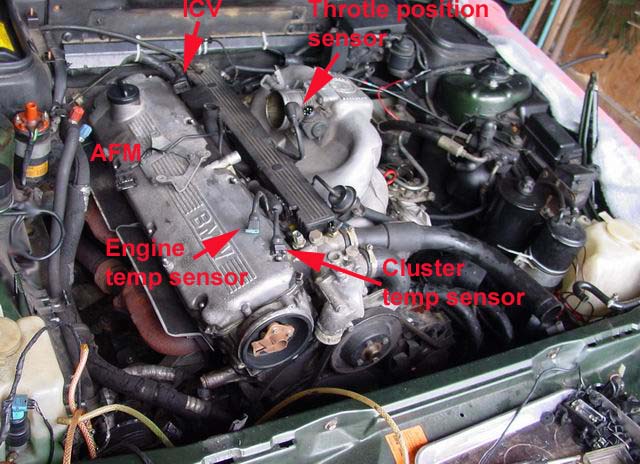

You may wonder what happened to all the electrical plugs, the ICV, the AFM, the spark wires and the dizzy cap.

Well I had a friend remove those while I was making a big mess covering the floor with coolant and ATF.

Removing the wiring harness from the injectors always seems to be a PITA.

The two hex bolts are easy, but the clips holding it to the injectors are very annoying.

Some people report to just having pulled the entire plastic box off in one go.

As that didn’t work for me I had to remove all the clips holding the rail to the injector one by one.

Removing everything from the topside went well. So time to get under the car.

I choose to use drive on ramps as it leaves more space under the engine for me to work.

Obviously I didn’t drive on to them at this point. Actually I’ve never been able to drive a car up those ramps.

First, third and fifth thing to do under the car is soak the exhaust bolts in penetrating oil. You don’t want to break them now do you?

The last time I removed the alternator to change the voltage regulator unit it took me 1.5 hours! This time just a couple of minutes.

While you are down there on your back you might as well undo the power steering pump.

I wasn’t planning on replacing the 3 week old Pentosin fluid in the hydraulic system (see steering house replacement) so I hung the pump with a piece of metal wire so the hydraulic system could remain closed.

Less fluids on the ground 🙂

This fuzzy picture shows the bolt hole in the oil pan thru which you have to undo the three torque converter mounting bolts.

The transmission has 11 bolts in total. Three of those can be reached from the top. The other 8 have to be removed from the bottom.

Be sure you have enough swivel pieces and extensions in your socket set. A 1/2″ extension set won’t allow you to reach all bolts so I also used a 3/8 socket set.

Also be sure to have a Torx E12 socket ready. At this point I left two bolts loosely in the transmission as there was already a gap the engine and the transmission.

Filling the air conditioning system with r134a costs about 200 euro (approx. US$260 at the moment) in Holland.

So you can image I wanted to keep the gas inside the system. So I hung the aircon pump with some metal wire just like the hydraulic pump.

This time with two pieces of wire as the aircon pump weighs way more then the hydraulic pump.

After undoing the fuels lines the engine is ready for removal.

Well it’s almost ready for removal. You still have to remove the nuts holding the engine mounting brackets to the rubber engine mounts.

While tackling out the engine I removed the right engine mounting bracket. This gave me a bit more clearance around the aircon pump.

Another thing to know: the torque converter is really in love with the engine.

It keeps hugging the engine while you really like it to stay in the bell housing of the transmission.

This makes removing the engine a bit harder and it gives the floor a reddish colour 😉

So a bit of advice: first pry off the torque converter with a breaker bar before removing the engine.

Well this divorce is FINAL!

It took about 6 hours including coffee breaks and lunch to get to this point. Of course I did have some help.

The transmission without the torque converter. Here you can see where all the bolts should go.

A good time to replace the seal from the gearbox to the torque converter.

The scenic view of the left side:

And the scenic view of the right side:

Look at the space between the wheel and the arch!

I used a jack to support the front side of the transmission. This made moving the car impossible.

So I took the job upon myself to be a human transmission mount while others had to push the car from under the engine 🙂

The “new” engine was dropped into place using the seat belt supplied by the seller:

Only half a day to go to get everything back.

As you took everything off you know where to put it. So “refitting is the reverse of the removal”…I still hate it when I read that in a service manual 🙂

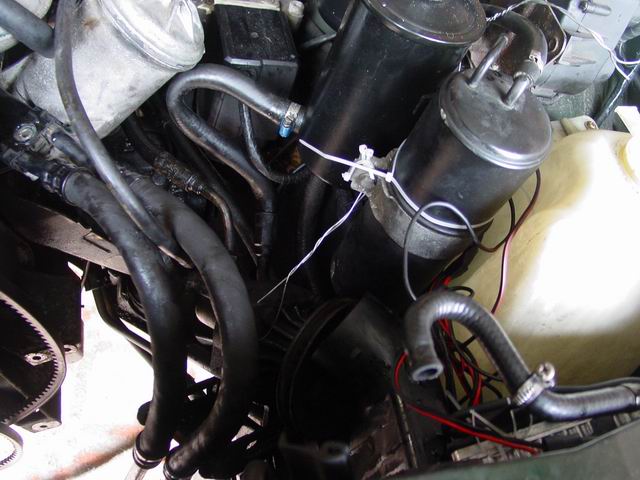

Just to give you an idea of the workspace:

Problems encountered: As my car is a very early e32 it has the prehistoric engine design (pre 11/87).

So the new engine had a different connector for the oil level sender, a different bracket for the crankshaft position sensor and some more minor differences that didn’t matter while refitting.

Solution for the sensor was to bolt the old sensor to the new bracket. The reason I did this was that the sensors do have a different part number but they look very similar.

Also as I was using the early injection system it made sense to use the early sensor.

The new bracket allows you to adjust the gap between the teeth on the vibration damper and the sensor.

This gap should be about 1mm. If it’s way too big the engine might run a bit rough.

As to the oil sensor I decided to solder the square connector to the existing wiring harness. Luckily I kept all the plugs from the 88 735iL I dismantled last year.

As for the wiring colours: BMW made a mess of this one. For proper working you have to solder the white wire of the new plug to the purple wire of the old wiring loom and the yellow wire on the new plug goes to the white wire of the old wiring loom.

Of course while working I made the mistake of joining the two white wires and the purple to the yellow. So I drove around for four weeks with the “oilsensor” error.

As I had no idea of the new engine’s oil consumption this annoyed me every time I got to see the message.

Skills required: Only for experienced DIY with access to a lot of tools.

Time spent: Well let’s say I managed to ditch my family all Easter weekend 🙂 It took me 1.5 day to remove and reinstall the engine. Another day was spend to prepare the new engine. And finally I needed another half a day to clean the mess I made.

| BMW Part Number | Description | Price | QTY | Sub-Total |

| 11 61 1 726 016 | Gasket (intake) | $1.30 | 6 | |

| 11 61 1 723 656 | Gasket w/ heat protection shield (exhaust) | $15.48 | 2 | |

| 11 42 9 063 138 | Set oil filter element | $7.74 | 1 | |

| 12 12 9 061 869 | Spark plug Bosch W8LCR | $3.28 | 6 | |

| 11 13 1 315 154 | Gasket (oil pan) | $15.72 | 1 | |

| 11 12 1 730 231 | Gasket (valve cover) | $16.62 | 1 | |

| 11 14 1 250 073 | Gasket (crank shaft seal housing) | $.85 | 1 | |

| 11 14 1 249 533 | Rear crankshaft seal | $29.16 | 1 | |

| 11 51 1 265 654 | Gasket (water pump) | $.82 | 1 | |

| 11 22 0 616 143 | Bolt (flywheel) | $1.30 | 8 | |

| 17 21 1 742 635 | O-ring (transmission cooler) | $.15 | 2 | |

| 11 62 1 711 954 | Self locking hex nut (exhaust manifold) | $.26 | 12 | |

| 24 31 1 422 671 | Shaft seal (gearbox input) | $6.04 | 1 | |

| Total |

An M30 3.5 engine can be found between 300 and 1000 euro in Holland or Germany.

Total cost? You do the math. I’m still living in denial! 🙂 Don’t forget to add 5.75 l of 15w40 oil, 3l of Dexron II/III oil,12l coolant,…etc. I keep telling myself it had to be replaced anyway!