Article by: Sean

Article applies to: all e32 and e34 models.

Problem:

A bird smashed into my windscreen doing about 170 kmh/110 mph and the impact scared the bejesus out of me.

Although it cracked the window severely, the inside layer of the laminated windscreen kept things together and I drove it for several months until I decided to replace it.

This gave me time to think things over: Can I do this myself or should I bring it to a shop? Should I buy a used windscreen from a salvaged 7 or should I buy a new one?

How could I remove the old windscreen from the car without breaking the window and let thousands of pieces of glass fall into the car and ventilation system?

I called several shops to inquire for prices and the differences where great.

The prices where varying from 240 euro/US dollar to 400 euro/US dollar, that’s labor and a new windscreen.

Just a new windscreen, to install it myself, was about 190 euro/US dollar. A used windscreen was about 80-90 euro incl. shipping.

I still couldn’t make a decision…but I never replaced a windscreen before, and several people told me this was not a do it yourself job.

But I just hate the fact that other people are working on my car.

Most of the time they are gorilla’s doing the job in a rush, damaging parts, messing things up, working much too crudely and giving me the overall idea that I just should do things myself, so I know the job is done well.

I don’t have much confidence in other people. Lots of people nowadays don’t have the slightest clue about what they are doing and aren’t interested in doing a good job.

Anyway, somebody pointed me to a certain shop where he had replaced his windscreen and had good experiences with it.

And they could do the job for about 200 euro/US dollar (labor and new windscreen!), which is an absolute bargain. It isn’t likely you can do it yourself for less, so I decided to bite the bullet and let them to the job.

So again: I didn’t do it myself, but I took some photographs while they did the job, so you can learn from it. Maybe then you can take the decision to do it yourself.

But when the windscreen was replaced and the job was almost done, something happened which gave me confidence that I had taken the right decision to let other people to this job.

Read on.

Background:

The e32 has a green tinted, laminated windscreen, which is cemented with the body (later years could have different colors).

This makes it hard to remove, you have to find a way to cut the adhesive sealant holding the windscreen to the body.

And it’s though sealant, those German engineers did not use supermarket stuff.

The windscreen is heated at the bottom (yes…every E32 has this feature), to prevent windshield wipers freezing to the glass.

For that purpose, it has 2 electrical terminals, 1 at each side. The anti-glare strip above is a factory option, but it’s hard to find a windscreen without it.

The ornamental strips are mounted to the windscreen with plastic clips. These clips stick to the glass with adhesive strips. . .

You can reuse these clips or use new ones. It is strongly suggested that you first mount the strips and clips to the new window and install window with strips as in 1 piece. The photo’s are showing this procedure.

Let’s start unbolting and removing parts:

First, the ornamental strips where removed. Do this very carefully, as these strips costs a small fortune at the BMW dealer (really, this isn’t a joke. 2 strips are more expensive than a new windshield):

Removal of the windscreen wipers, which was quite difficult:

Clips and lower covers removed, and of course some clips where damaged while doing that and later one, some clips mysteriously disappeared:

Removal of the several clips by prying them out sideways:

Close-up of the removed clips:

This is the most interesting part. To cut the sealant, they used some sort of special tool.

The blade cuts the adhesive caulking compound around the windscreen.

This isn’t an expensive tool, costs about 12 Euro/US dollar:

At the bottom of the window this device couldn’t be used.

So they used some special wire with 2 handles and sawed the windscreen loose by pulling the wire back and forth (2 people needed for this job):

Notice a third person at the right was lifting the partially loose windshield a bit up to give enough clearance:

And the windshield could easily be removed:

Discarding it:

Removing the old sealant with some sort of chisel:

And unfortunately . . . AAAAAAARRRRGGHHHHHH . . . RUST!!!!!!!

Notice that the factory spot-welds where rusting . . .

I was not amused at all. Also the paint and primer where damaged during the sealant removal, that is almost inevitable.

The factory manual says about this: Touch up paint finish damage with zinc dust paint and enamel:

The rust was sanded away (well, as good as possible), and the damaged paint slightly sanded:

Applying paint primer:

While the primer dried, the new window arrived:

These are the terminals for the window heating, one at each side. It was just a wire and the terminal of the old shield has to be used:

The inside mirror connection was glued to the windscreen with some special glue:

The inside of the glass has a coat of glass ceramic at the edge area.

This is ultraviolet protection for the adhesive sealant.

This area must also be (just like the edge of the body opening) brushed with primer and therefore thoroughly de-greased:

Applying the primer to the ceramic edge area:

The old ornamental clips where reused. First the clips where attached to the windshield, and after that the strip was attached to the clips:

In the meantime, somebody else was applying a bead of sealant on the body opening.

He used a 1 component (1K-PUR) polyurethane adhesive cement:

A close-up:

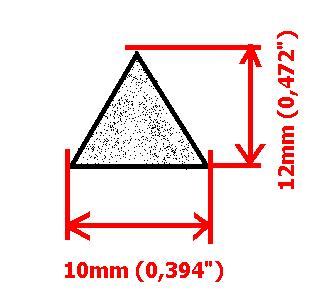

This is the shape to give you an idea:

Sorry for the not so sharp picture.

After applying the sealant, someone used a screwdriver to ensure it’s a nice triangle of sealant, achieving that it’s well bonded and has no air pockets or gaps:

Ready for window installing:

With 2 people the new windshield was installed, carefully pushing the window into the sealant and making sure the ornamental strips align with the body:

A very strong sort of tape was applied, probably to prevent the window from slowly moving downwards while the sealant dried.

They didn’t remove it the same day, I was told that I should remove it one day later when the sealant fully hardened:

Connecting the lower window heater:

And now comes the hard part….after applying some pressure by them to the window, making sure it was seated right, the new window cracked:

I wasn’t in a good mood that moment, neither the guys and certainly not the shop-owner . . .

Man, was I glad I didn’t install the window myself.

They immediately removed the new window, before the sealant dried.

So the second window was discarded:

And the whole story started again, see picture one. Sigh.

It took whole afternoon, and finally I drove home with the third window in a row that day . . .

Remark after 2 weeks:

The second window didn’t seated as beautiful as the first one, because they where very careful now and where afraid to apply to much pressure to the second window while installing.

So I did suffer from wind noise while driving after the replacement. I sealed the ornamental strips (which had a slight gap between strip and body) up and now everything is all right.

Total amount of time :

Depends on how many windshields you will break while installing

Skills needed/difficulty level :

Don’t be surprised that this is no DIY job, although next time I’ll try it myself with a used one.

Satisfactory level after the job done :

I bought a couple of new windshield wipers and the new sight is really amazing.