Article by: 8Tech

Article applies to: all models with the M70 V12 engine.

Ok, so the next chapter in my eagerly awaited, is how to install an engine oil cooler on the V12.

I have a slight advantage as with a CSi I already have one but with the mods required here, I may as well not.

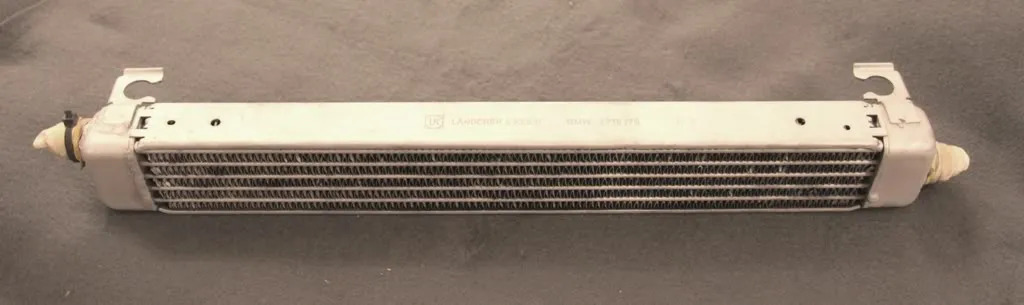

My original idea was to remove the cooler and give it a good flush through and a repaint as the matrix had got very corroded and powdery as seen before on these alloy radiators.

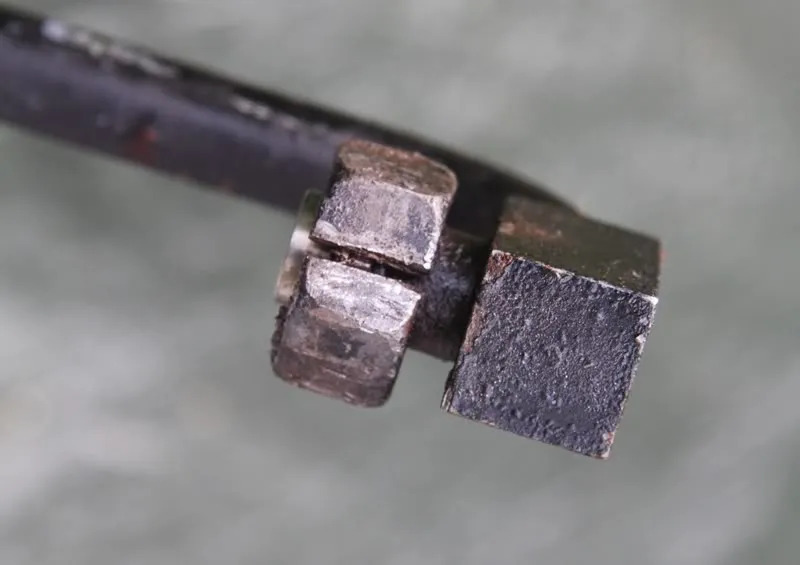

Well, my first disaster was a completely seized union on the longest hose that would not even come undone with heat so desperate means were employed.

I had to cut the union off to remove it, done carefully without damage to the cooler threads.

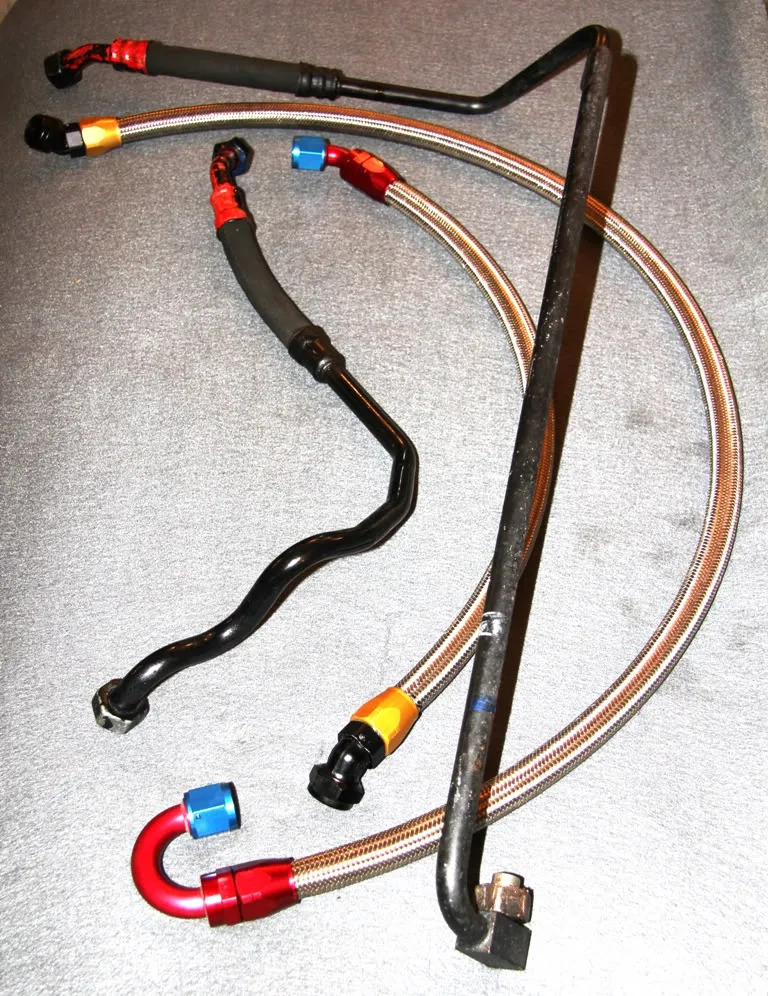

Destroying the hose meant replacing it and as the OEM hose was so expensive, I decided to go the braided hose route.

The problem here is that the car uses 22mm fittings and these are not available in the fittings I needed, so further mods were necessary.

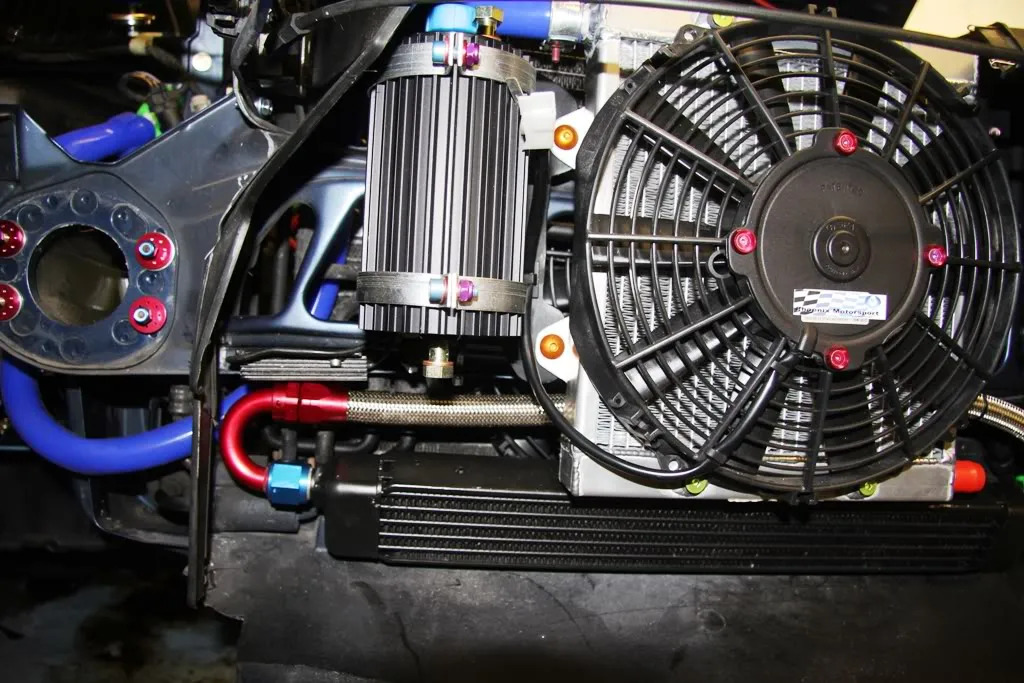

I had to cut the end fittings from the cooler and weld in new 7/8″ JIC flange fitting to take the new -10 hose.

I then sealed off the ends and blasted the cooler matrix clean.

Followed by a nice coat of heat dissipating paint.

The new -10 JIC hoses I had made up, mated with some M22 fittings on the other end. These routed the original way back along the underside of the radiator.

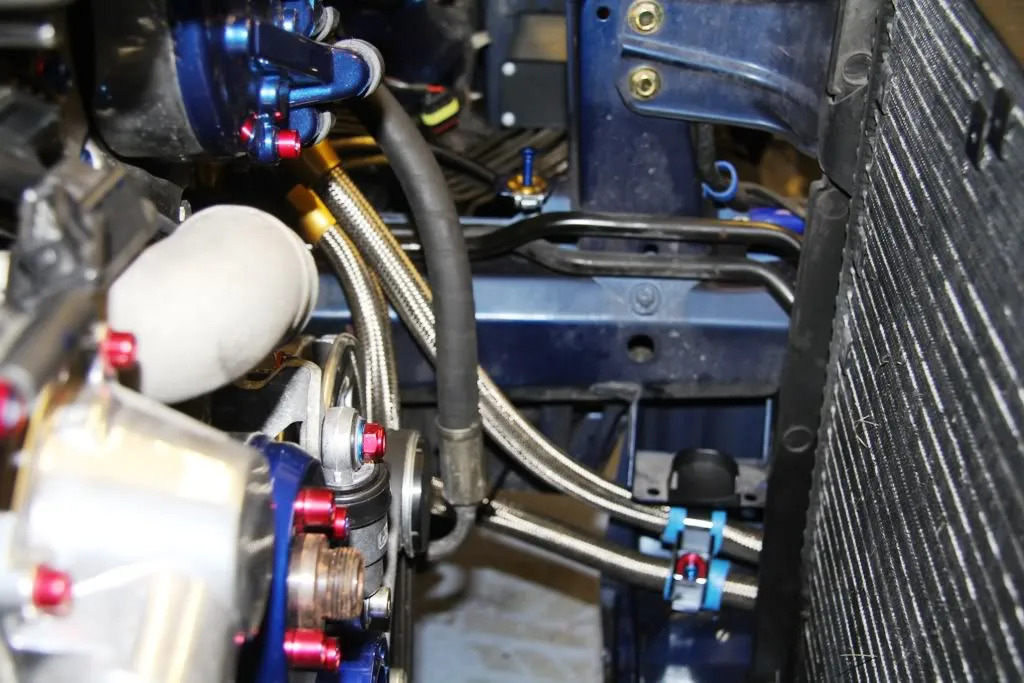

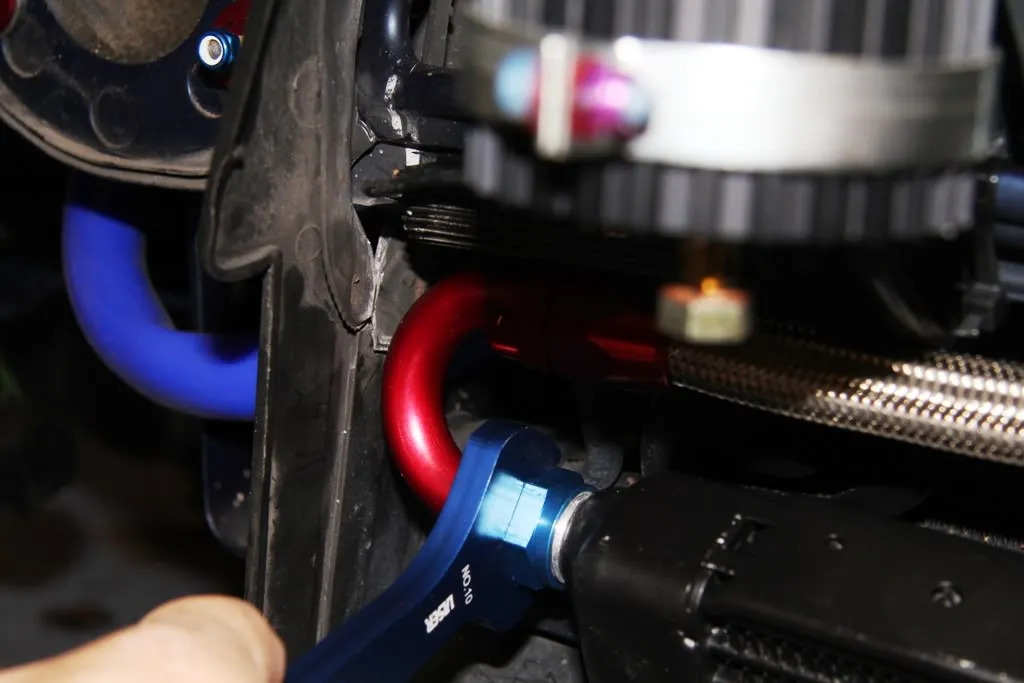

Using the 2 large self tapping screws to mount the matrix, it was refitted and the new hoses fitted very loosely.

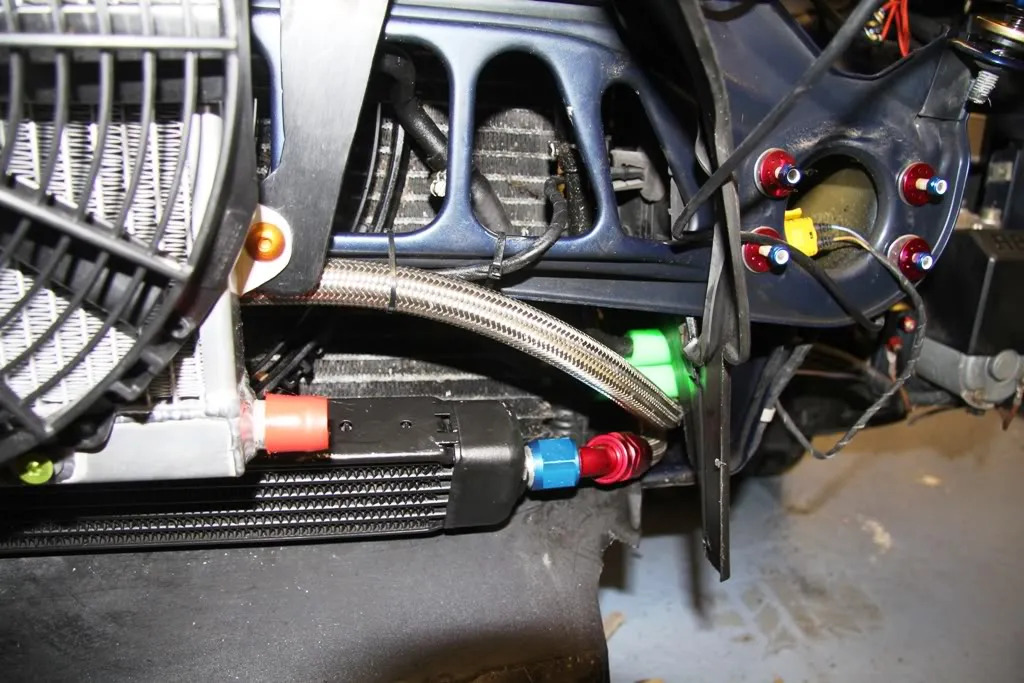

So that they would freely rotate on their swivel joints and allow the correct alignment at the filter housing end where the new 22mm forged fittings.

Complete with new “O” rings connect to the housing through the 22mm to 27mm alloy adapters.

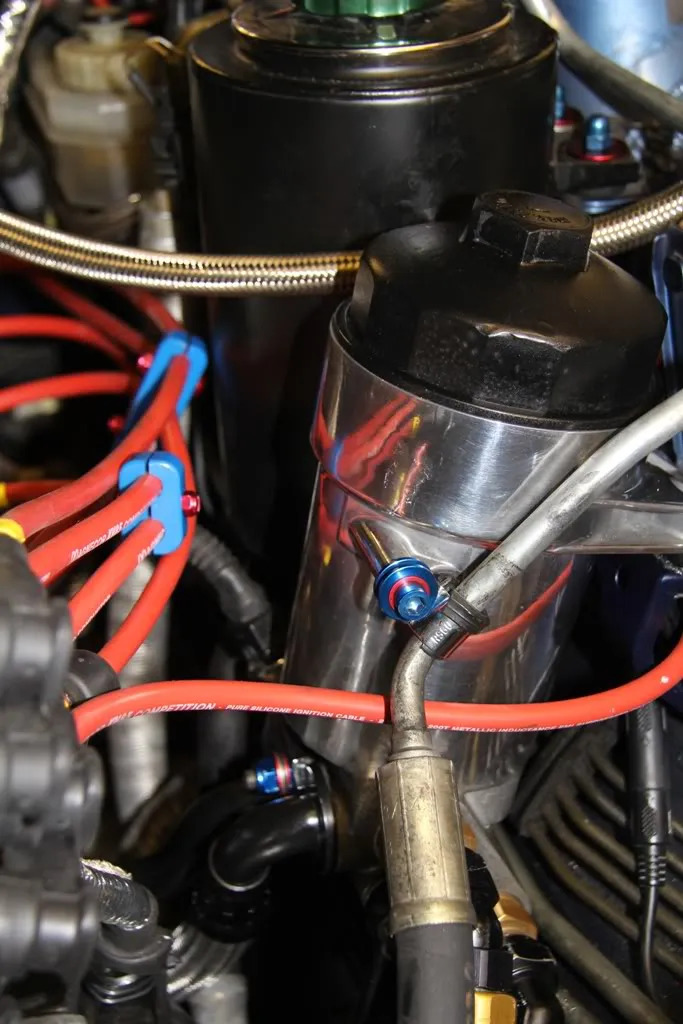

Next the oil banjo bolt can be fitted with new crush washers . . .

the engine block to filter housing braided hoses refitted with new “O” rings . . .

and the Pentosin line re-attached.

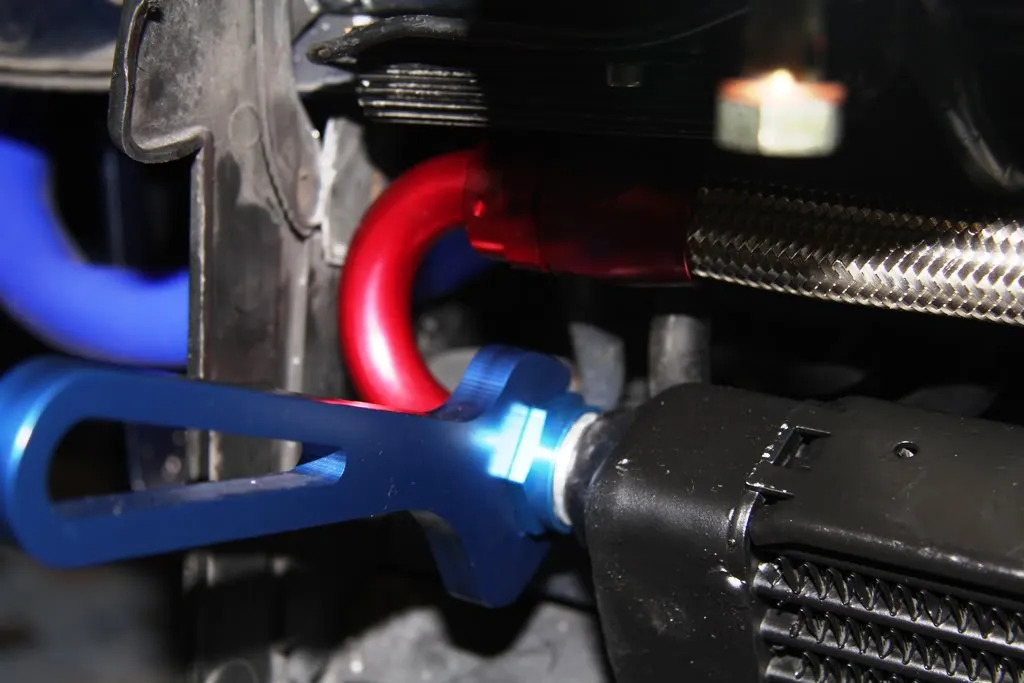

You can now tighten the M22 fittings on the oil housing which can be seen here fitted with my safety mounting kit.

followed by the left hand fitting . . .

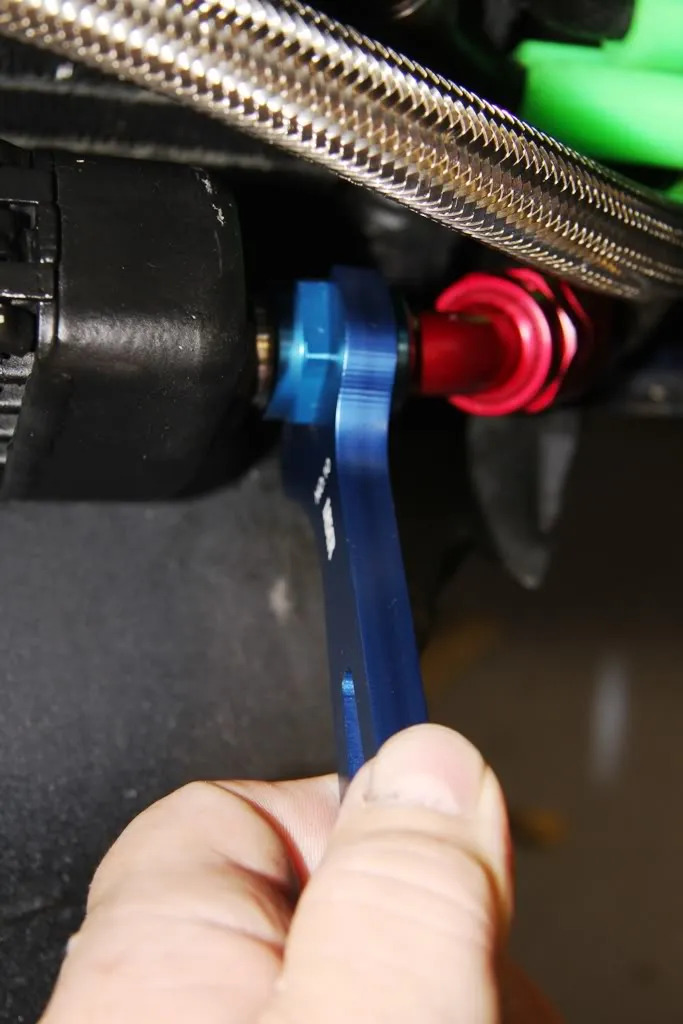

and the right hand fitting.

With the end fittings now tight, the swivel is fixed on each end . . .

and all that there is left to do is refill the system with oil and check for leaks.